Loconet Wiring is an essential component in model railroading that allows for the seamless integration of various devices and accessories on a layout. It is a system that enables communication between different components, such as DCC controllers, decoders, and sensors, ensuring smooth operation and control of the entire layout.

Why Loconet Wiring is Essential

Loconet Wiring plays a crucial role in model railroading for the following reasons:

- Facilitates communication between different components

- Enables centralized control of the entire layout

- Allows for the expansion and addition of new devices and accessories

- Ensures reliable operation and smooth functioning of the layout

Reading and Interpreting Loconet Wiring

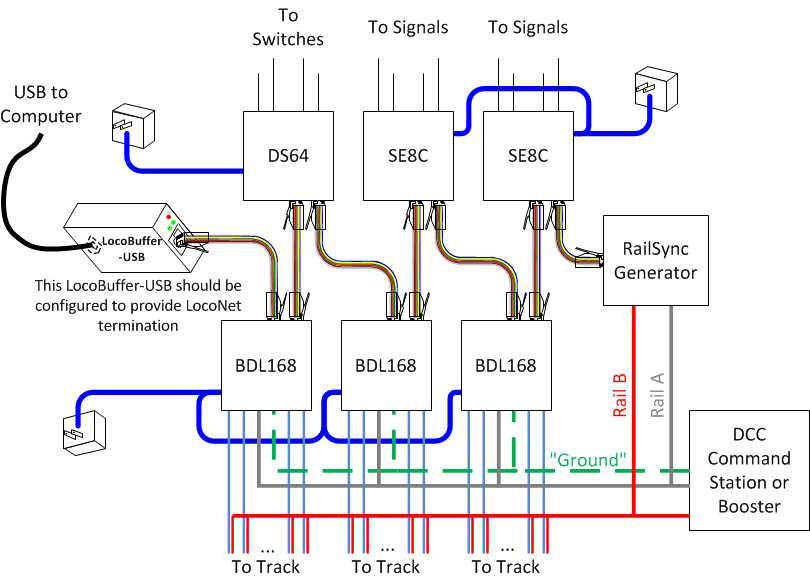

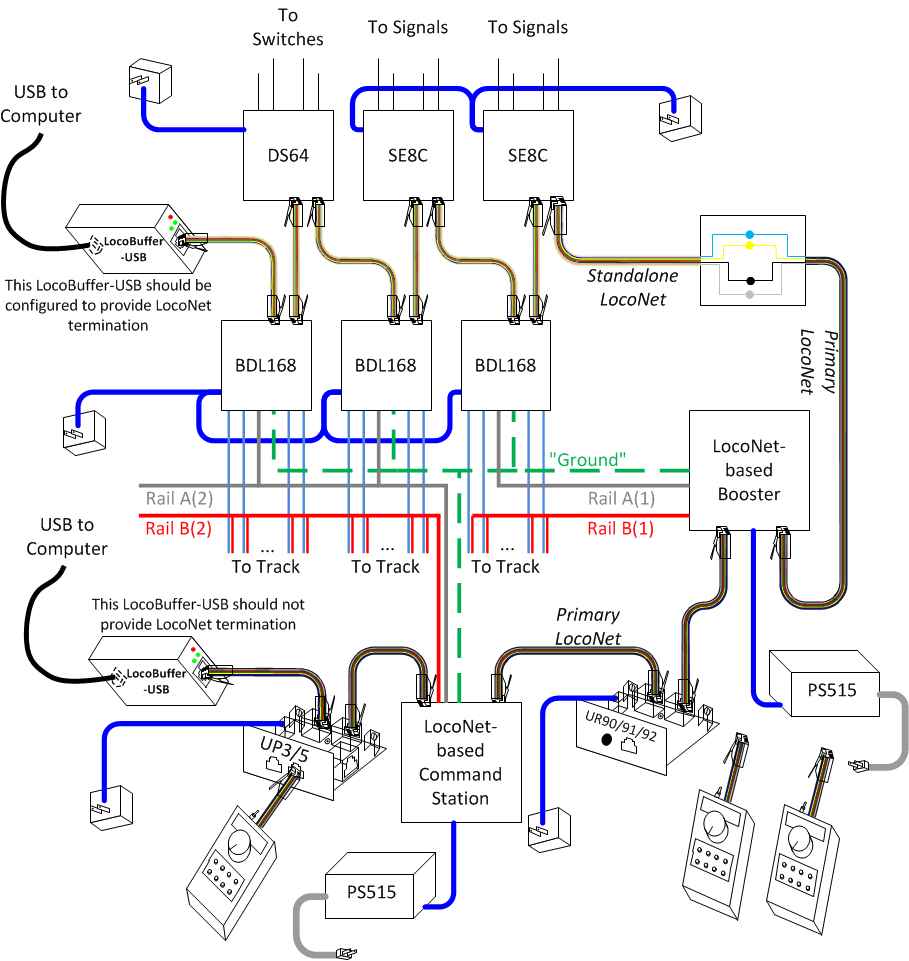

When working with Loconet Wiring, it is important to understand how to read and interpret the wiring effectively. Here are some tips to help you navigate through the wiring diagrams:

- Identify the components connected to the Loconet Wiring

- Follow the color-coding scheme to differentiate between different wires

- Pay attention to the connections and their corresponding labels

- Refer to the manufacturer’s instructions for specific guidance

Using Loconet Wiring for Troubleshooting

Loconet Wiring can also be a valuable tool for troubleshooting electrical problems on a model railroad layout. By understanding how the wiring is connected and structured, you can easily identify and resolve issues such as shorts, open circuits, or faulty connections. Here are some steps to effectively use Loconet Wiring for troubleshooting:

- Inspect the wiring connections for any loose or damaged wires

- Use a multimeter to test for continuity and voltage along the wiring

- Follow the wiring diagram to trace the path of the current and locate any potential issues

- Consult with other model railroaders or experts for additional assistance

Importance of Safety

It is crucial to prioritize safety when working with electrical systems and using wiring diagrams. Here are some safety tips and best practices to keep in mind:

- Always turn off the power before working on any electrical components

- Use insulated tools to prevent electric shocks

- Avoid working on wet surfaces or in damp conditions

- Double-check all connections before applying power to the system

Notebook

Notebook

JMRI Hardware Support – Standalone LocoNet®

20 Images Loconet Wiring

Woodstock Model Railroad: Digitrax wiring

20 Images Loconet Wiring

8’ LocoNet Cables-2 Pack

JMRI Hardware Support – Standalone LocoNet®